Lamination is a technology that ensures that paper bag products are of higher quality, stronger, more durable and more modern. Briefly; It is the bringing together of multiple different materials by applying pressure with the help of heat and/or some kind of adhesive.

1 Paper Bag / Weight

| American Bristol | 185 gr/m2 200 gr/m2 250 gr/m2 300 gr/m2 350 gr/m2 |

| Double-Sided Coated White Paper | 160 gr/m2 170 gr/m2 200 gr/m2 250 gr/m2 |

2 Printing Applications (Finish) for Paper Bag

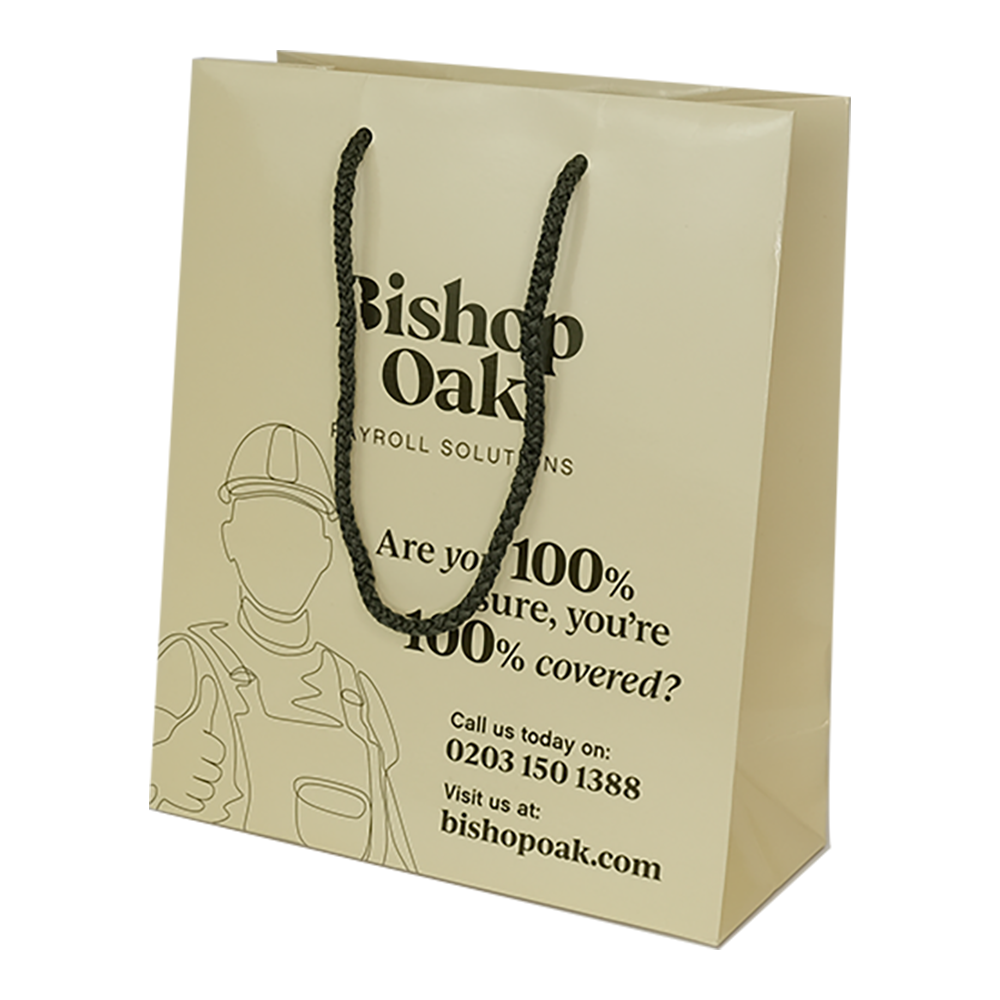

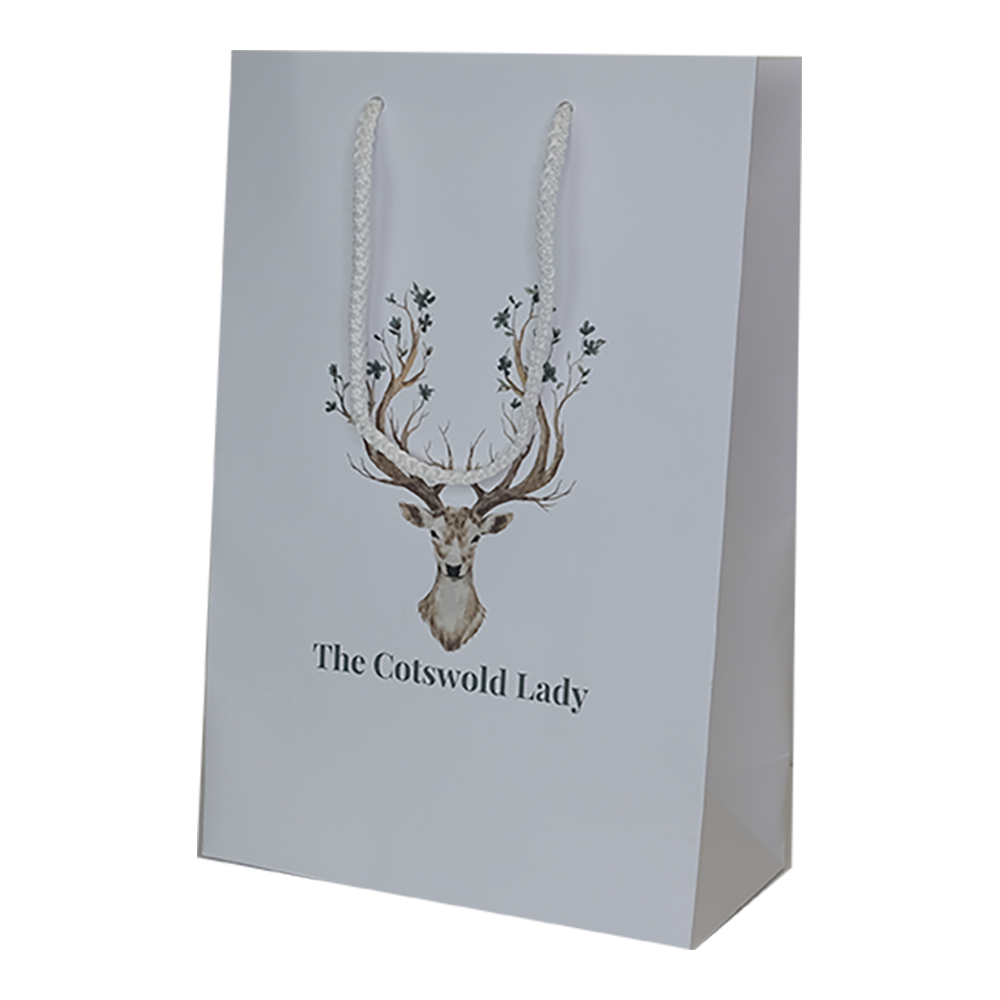

| Color | CMYK, HKS, Pantone |

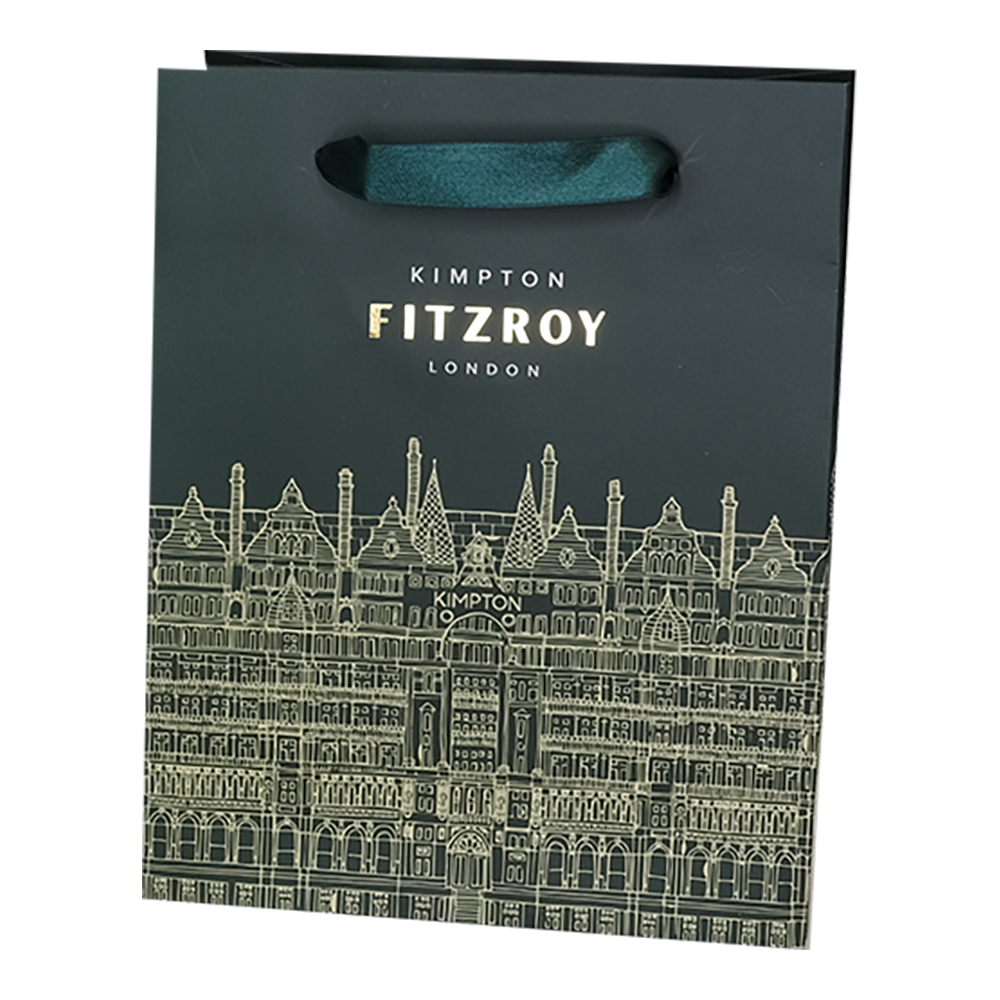

| Lamination | Matte, Glossy, Metallized, Anti-Scratch Matte, Velvet |

| Varnish | Matte, Glossy |

3 Post Printing Applications for Paper Bag

| Embossing | Embossing Debossing Line Embossment Pattern Embossed |

| UV Varnish | Matt, Glossy, White |

| Hot Foil Stamp | Our standards are silver, gold, copper. Please contact us for other colors. |

| PVC Window | It can be made in allshapes and sizes. |

4 Handle - Ropes for Paper Bag

| Ropes | Polyester Rope Cotton Rope Polyp Rope Twisted PP Rope Ecological Paper Ropes |

| Ribbons | Satin Ribbon Grosgrain Ribbon |

| Die Cut Handle -Eyelet -Die Cut Hole | It can be made to the desired extent. |

Herringbone and

Flat Extrafors | Herringbone and Flat Extrafors |